Summer Internship | Amber Enterprises (June 5 – July 20)

Project: Window AC Front Fascia Grill Design

Overview

During my two-month internship at Amber Enterprises, a leading manufacturer of indoor and outdoor AC units, I was tasked with designing a front fascia grill for a window AC. The challenge was to retain the essence of traditional designs while introducing a fresh, modern twist to enhance aesthetics and functionality.

During my two-month internship at Amber Enterprises, a leading manufacturer of indoor and outdoor AC units, I was tasked with designing a front fascia grill for a window AC. The challenge was to retain the essence of traditional designs while introducing a fresh, modern twist to enhance aesthetics and functionality.

Timeline & Process

1. Research & Ideation

• Conducted market study of existing AC fascia designs.

• Identified common patterns and functional requirements.

• Brainstormed ideas to balance tradition with innovation.

(1) Moodboard/references

2. Concept Development

• Sketched over 50 unique grill pattern concepts inspired by existing design language.

• Narrowed down to 20 refined patterns that aligned with both brand identity and functional requirements.

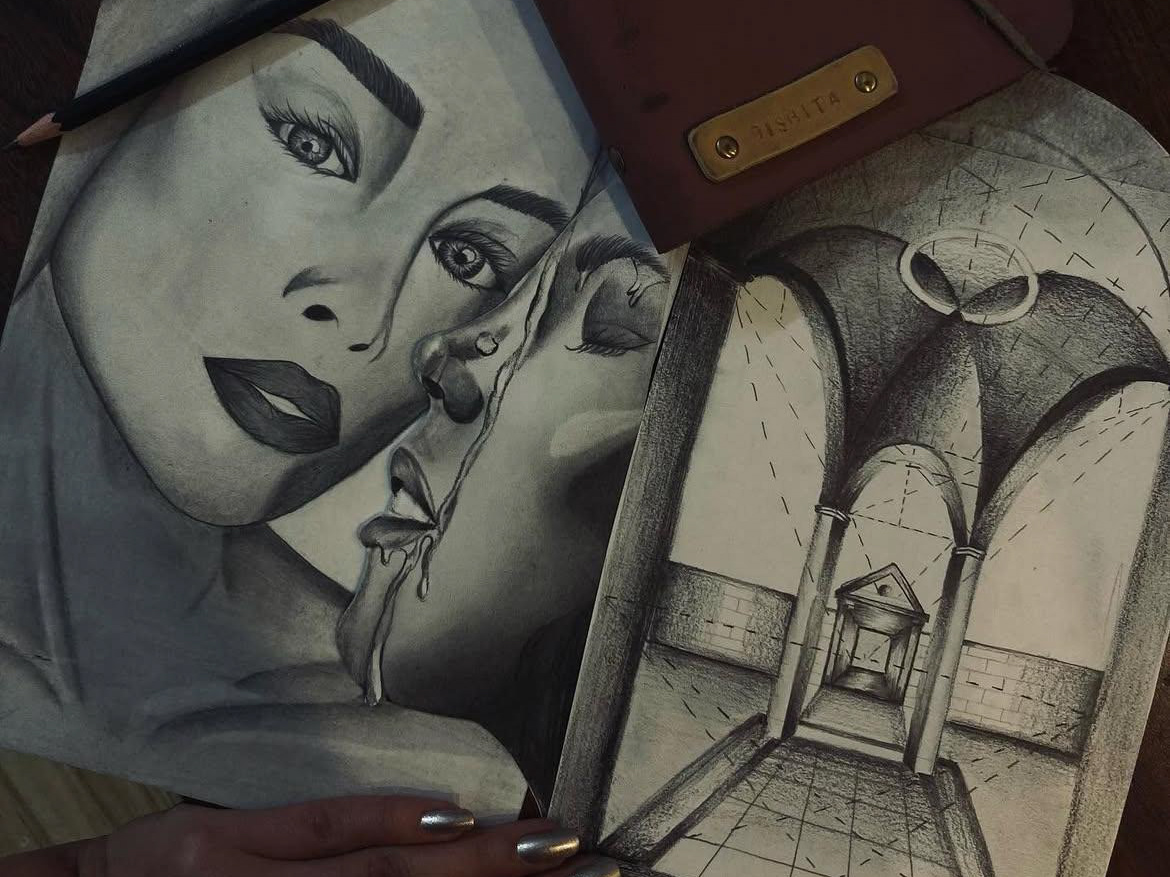

(2) Initial Sketches

(2.1) Initial Sketches

3. Visual Prototyping

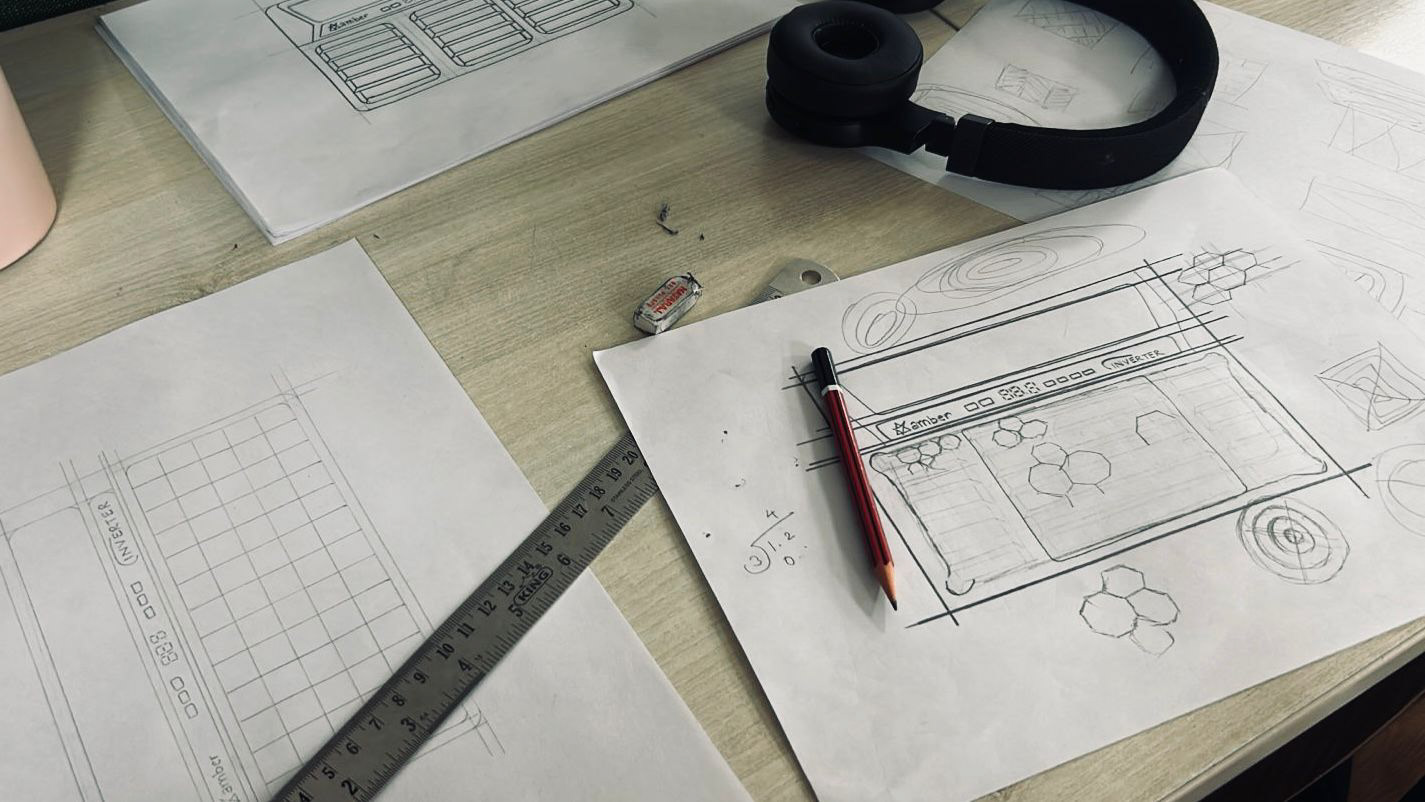

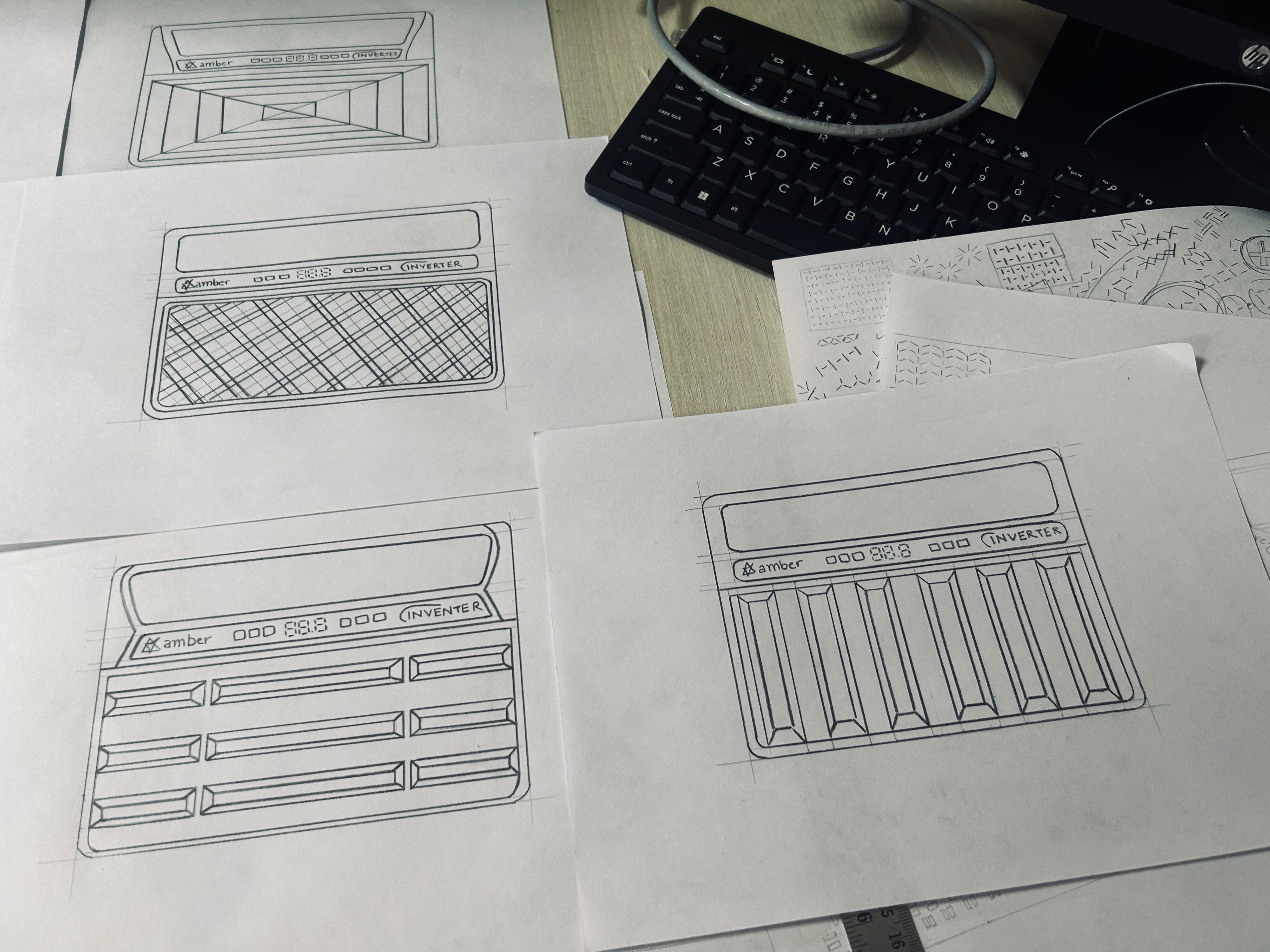

• Created full sketch models on paper of the AC front with my proposed grill mesh designs.

• Enabled visualization of the overall product integration and aesthetics.

(3) Hand-drawn AC facia sketches with grills

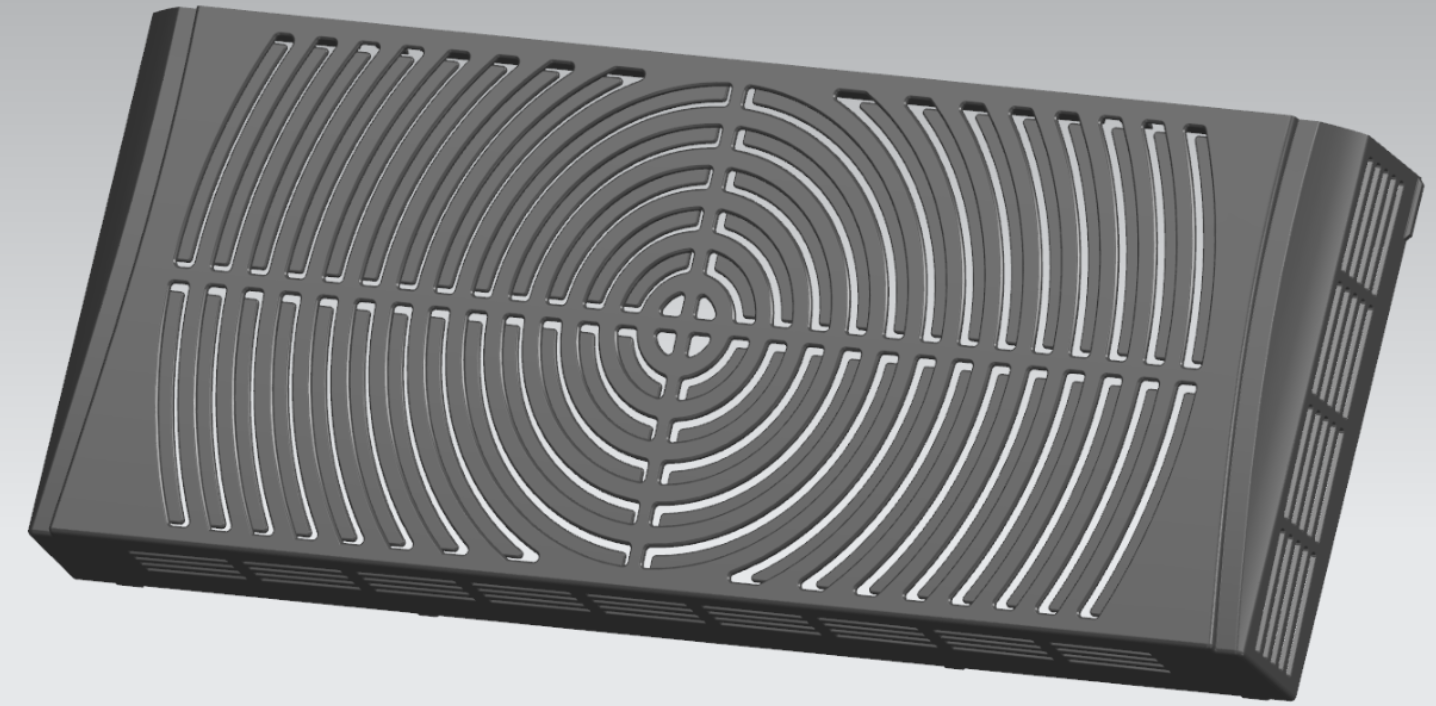

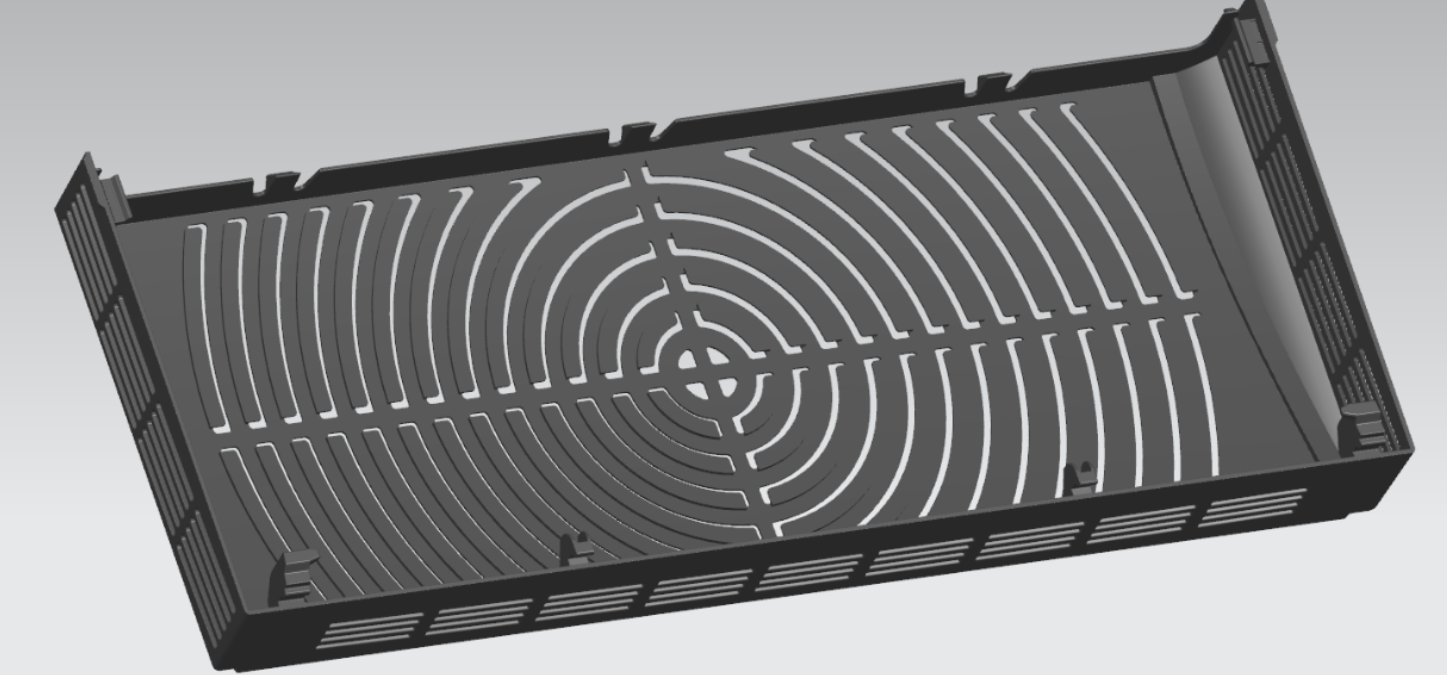

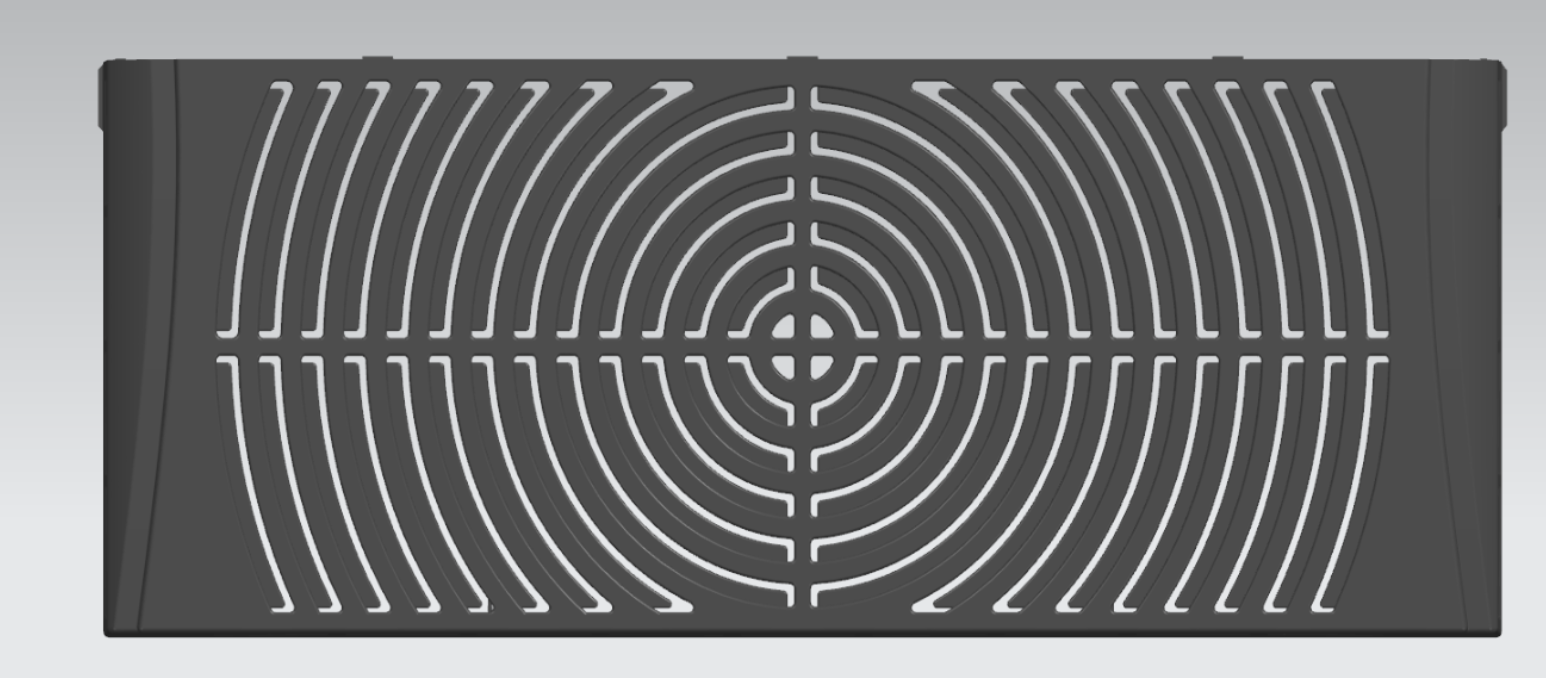

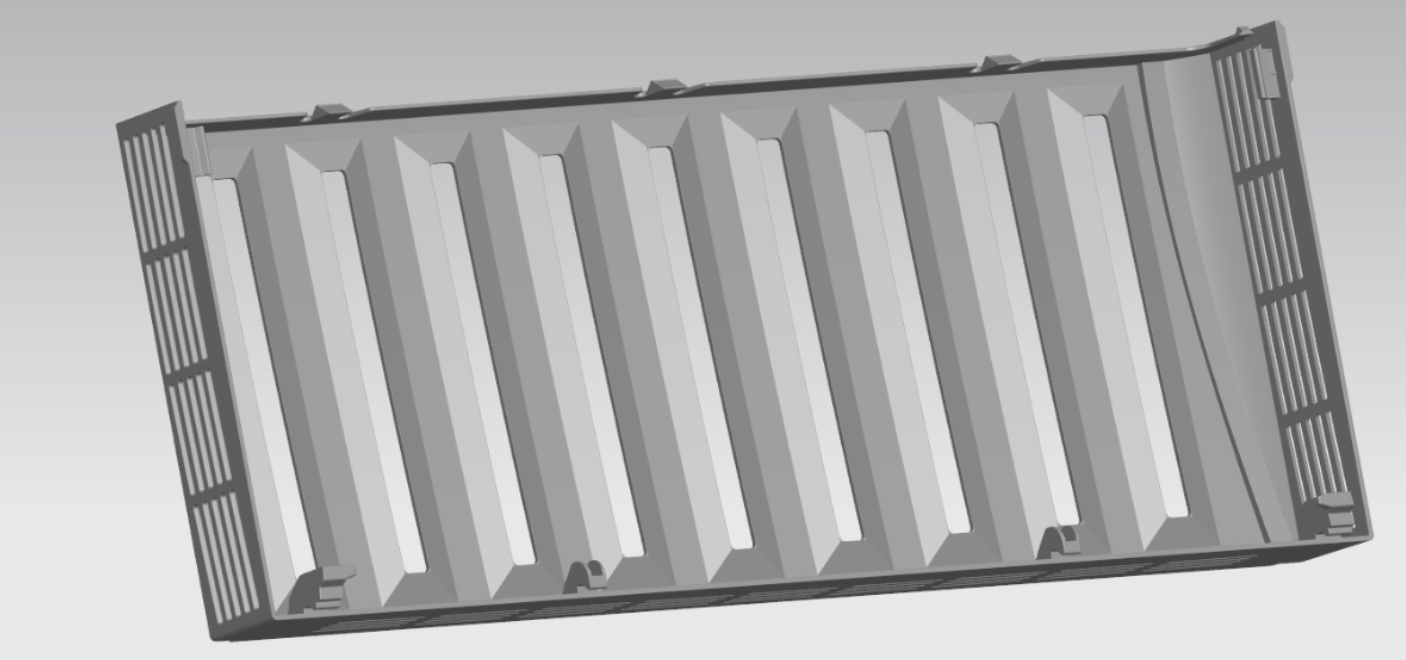

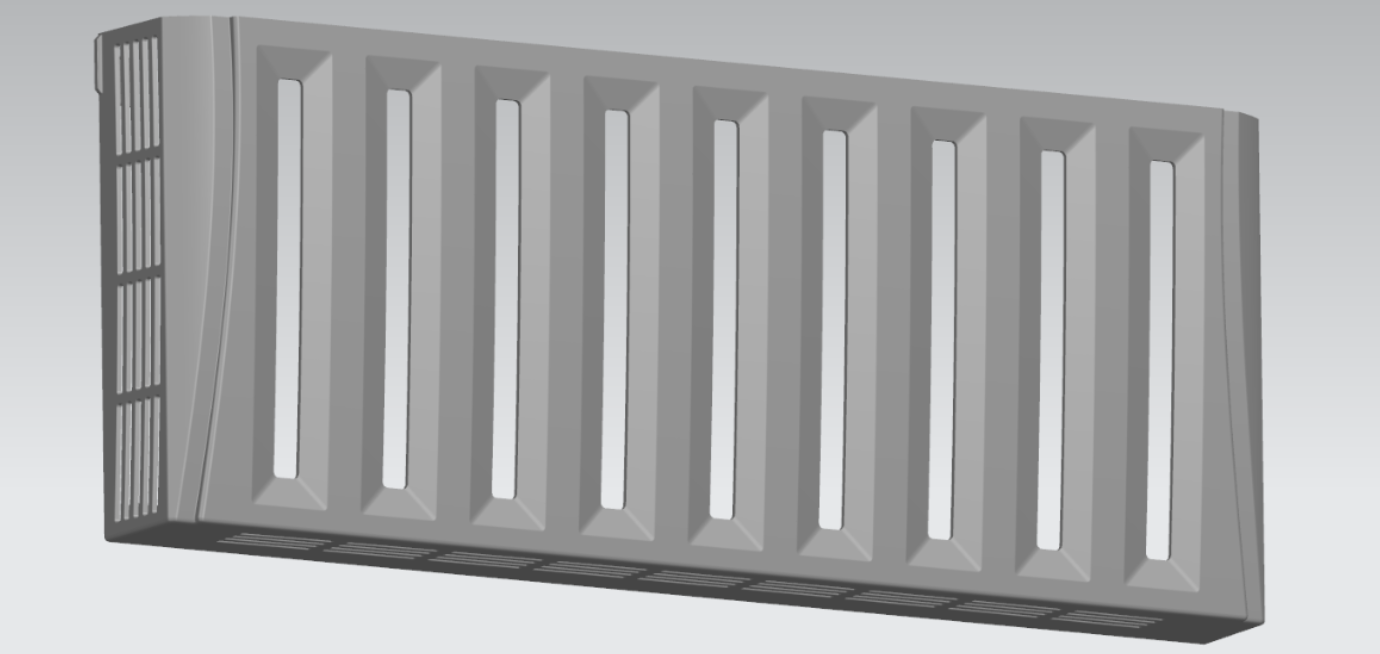

4. 3D CAD Modeling

• Four shortlisted designs were developed in Siemens NX CAD.

• Focused on detailing mesh geometry, airflow feasibility, and manufacturability.

5. Prototyping & Testing

• Two final designs were selected for 3D printing.

• Prototypes underwent rigorous performance and safety tests, including:

• Air suction & airflow efficiency

• Finger safety test (ensuring no finger, adult or toddler, could pass through)

Outcome

The internship provided hands-on exposure to industrial product design—from ideation and sketching to CAD modeling, prototyping, and testing. The project not only strengthened my technical skills in NX CAD but also taught me the importance of balancing aesthetics, function, and safety in real-world product design.